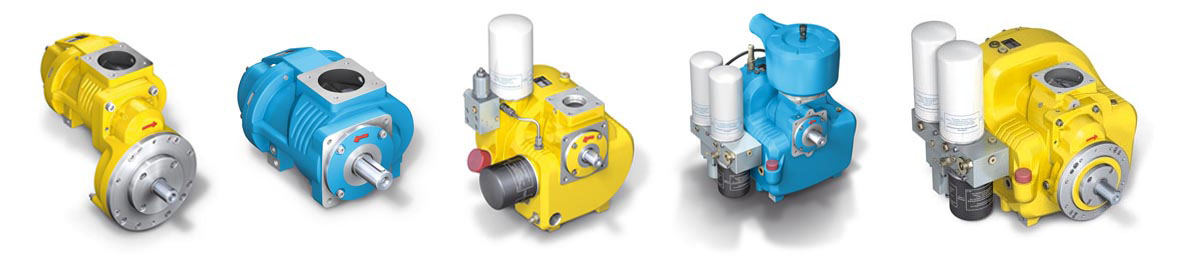

EVO® MAINTENANCE SOLUTIONS

ROTORCOMP® After Market Solutions

EVO® LUBE-SP ISO VG46/68

- available in viscosity 46 and 68

- low tendancy of evaporation

- exceptional protection of internal metal surfaces

- contains ashless anti-wear system to help prolong the life of critical parts such as bearings and gears

EVO® LUBE-HP ISO VG68

- NSF-H1 listed

- fulfill U.S. guidelines of sec. 21 CFR of FDA regulations

- excellent aging- and oxidation resistance as well as high termal resistance; RBOT according to ASTM D-2272

- very low foam-behavior according to DIN 51566

- low tendency of evaporation

- excellent demulsibility

- performs over a wide temperature range

TECHNICAL DATA

| Kinematic viscosity at 40º | Kinematic viscosity at 100º | Temp. range | Pourpoint | Container size | Article no. | |

|---|---|---|---|---|---|---|

| EVO® Lube–HP ISO VG68 | 68 mm²/s | 11 mm²/s | 50°/+140° | -55°C | 5 liter | N44085 |

| EVO® Lube–SP ISO VG46 | 46 mm²/s | 7,5 mm²/s | -10°/+110° | -48°C | 20 liter 209 liter | N44088 N44089 |

| EVO® Lube–SP ISO VG68 | 68 mm²/s | 10,2 mm²/s | -10°/+110° | -48°C | 20 liter 209 liter | N44090 N44091 |

MAINTENANCE KIT

- ROTORCOMP Maintenance solutions maximize the operational reliability

- OEM parts grant highest quality standards

- Regular service and maintenance prolongs the lifetime of a compressor

- Pre-picked service/maintenance packages makes logistics as easy as it can be

- Ensure performance and reliability

- Simplify your logistic

| Service kits............ | perfectly adapted to yearly service intervals |

|---|---|

| Filter kits................. | contains all filters required for yearly service |

| Maintenance kits | contains all wear parts that need to be replaced as preventive maintenance measure |